Vegetable processing line

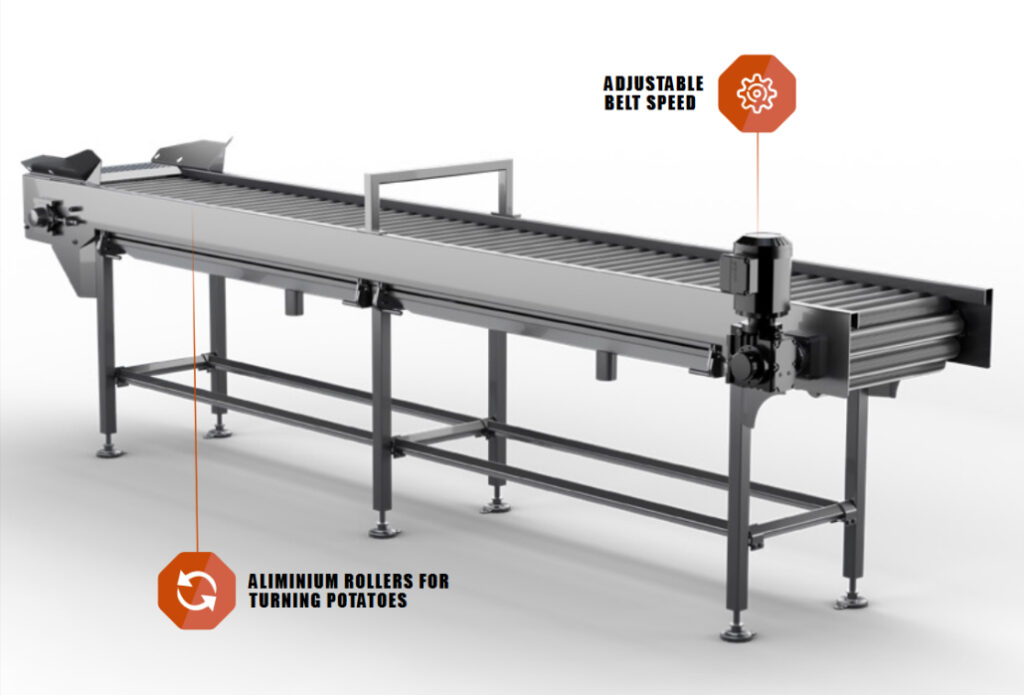

ROLLER INSPECTION TABLE

The need for manual inspection of all types of food products varies depending on the season and quality of the incoming products. The Roller Inspection Table has specially designed aluminum rollers. This ensures that the products turn and expose the entire surface to the staff at the inspection table. The speed of the rollers can be easily adjusted. The cut trimmings are collected in a container. The Roller Inspection Table can also be supplied with individual cutting plates for each inspector(optional).

Inspection Table Advantages

Adjustable belt speed

Aliminium rollers for turning potatoes

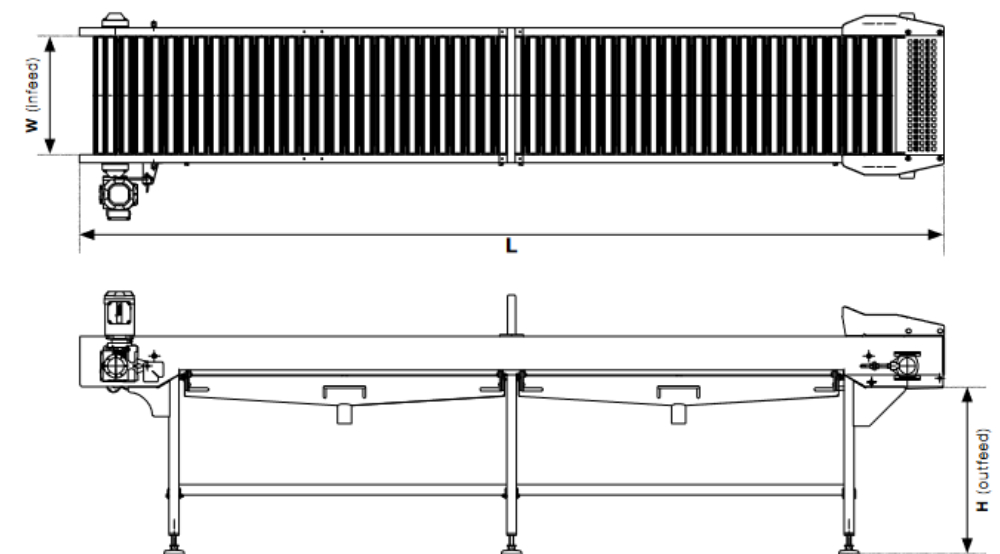

Roller Inspection Table

L(mm): 3000

W INFEED(mm): 600, 800, 1000

H OUTFEED(mm): 700

INSTALLED POWER: 0.75 kw

L(mm): 4000

W INFEED(mm): 600, 800, 1000

H OUTFEED(mm): 700

INSTALLED POWER: 0.75 kw

L(mm): 5000

W INFEED(mm): 600, 800, 1000

H OUTFEED(mm): 700

INSTALLED POWER: 0.75 kw

L(mm): 6000

W INFEED(mm): 600, 800, 1000

H OUTFEED(mm): 700

INSTALLED POWER: 0.75 kw

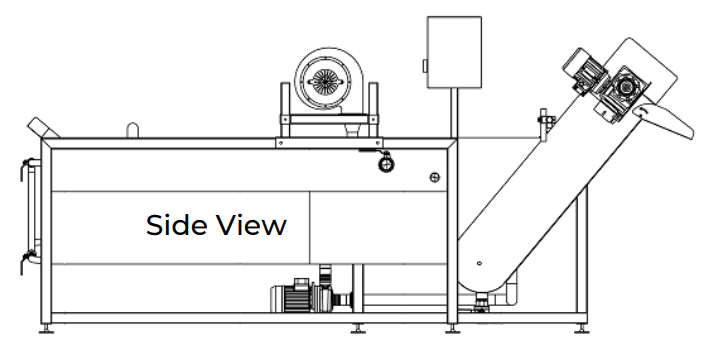

CONTINUOUS TYPE VEGETABLE WASHER

Industrial Fruit and Vegetable Washing Machine, also known as commercial fruit and vegetable washing machine, it is specially designed for cleaning fruits and vegetables, herbs. Our fruit and vegetable washer adopts high-pressure spray, bubble surfing, drum filtering and ultrasonic vibration or Ozone cleaning methods to thoroughly clean the dirt on the surface of vegetables and fruits. Besides, during the cleaning process, an appropriate amount of fungicide can also be added to clean vegetables and remove pesticide residues. While cleaning, materials can be washed completely and thoroughly without damages to material surfaces, taste, and nutrition of materials. The purified water filtered by activated carbon can be recycled, saving 80% of water. Our fruit and vegetable washer was widely used at the food processing plants and business.

Batch Type Vegetable Washer Advantages

Turbulant water flow/bubbles to wash all product separatly.

Adjustable conveyor speed and water flow.

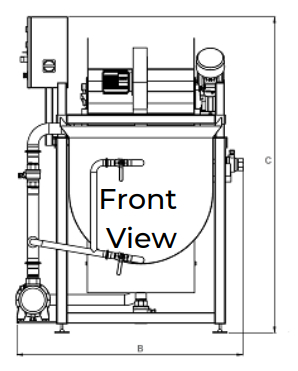

WASHER

VIBRATION DEWATERING TABLE

We build dewatering shakers in all shapes and sizes, it is an excellent technical solution for subsequently separating the water from the product. A shaker is a very hygienic and effective solution since the vibratory conveyor technology enables the shaker to break the water surface or drops of liquid on the products and remove the water.

The decks can be manufactured customspecific with wire mesh, wedge wire, perforated metal sheets or bars. The decks are easily replaceable – they are equipped with a quick tension system – so that the dewatering shaker can be used to transport and dewater multiple sorts and types of products.

Batch Type Vegetable Washer Advantages

Easy to use

Require Less Men Power

VIBRATION TABLE

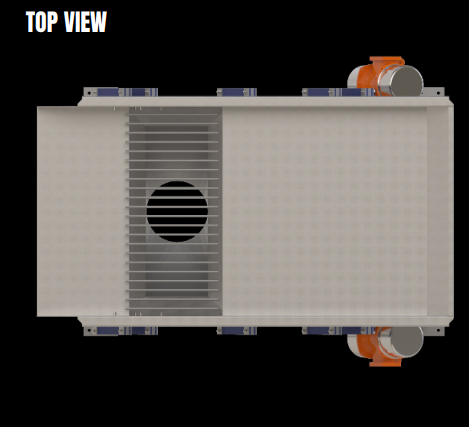

VEGETABLEAIR DRYING MACHINE

Air Knife Dewatering Machine is used for dewatering and drying hard and soft vegetable, salad, bay leaf, cut lettuce as well as fruit, etc. Air Knife Dewatering Machine can be optimized for removing excess surface moisture from products such as vegetables, salad, and fruit while keeping the product in perfect condition. With the possible adjustment, the machine can be optimized on product quality, residual moisture, and capacity. The product is transported on a conveyor belt and the speed of the belt is adjustable depending on the product. Several special air knives and blowers are dewatering the product whereas several blowers are distributing it over the whole width of the conveyor above each air knife. An air knife at the outfeed removes any remaining product from the conveyor belt.