Egg Washing

Egg washing systems

GENERAL

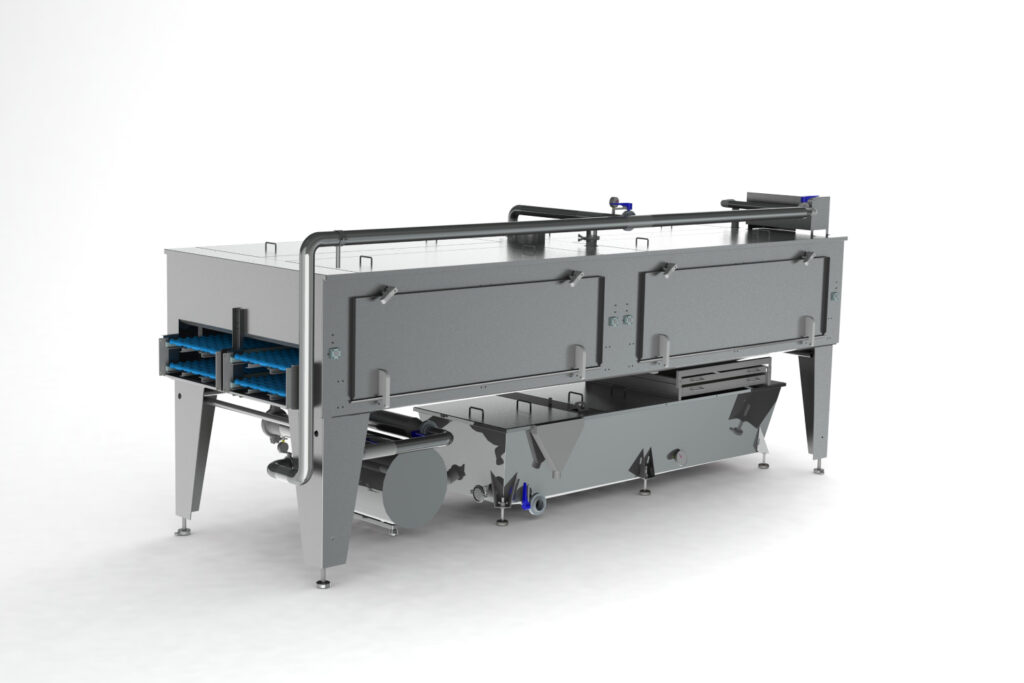

The AQUA ART & ENGINEERING modular egg washers are available in 6-8 rows and 12-16 rows cabinets. With combinaon of short and long modules any washing me is achievable. The egg washers can be installed with any egg drying, egg labeling, egg disinfecon, egg oiling, egg breaker and egg grader in thein dustry. Egg Washers are available with capacies from 3000 up to 19000 eggs per hour, and exist in two different types:

- The AAE Compact washers with washing cabinet with brush modules.

- Ÿ The AAE Modular Washers with a Double-Acon Washing System with a combinaon of brushes and spray nozzles.

The modular washers are available in different lengths and wash mes with a variable number of brush and spray modules for maximum washing performance for different qualies of eggs. The modular system prevents excessive washing with a onsequent loss of eggs and reduced yield.

OPERATIONAL DESCRIPTION

Eggs entering the AA&E Washer on the roller table are washed with brushes having a high egg – to – brush contact for an opmal washing. Integrated spray nozzles result in an improved egg cleaning (only on modular washers).

Nozzles are constantly spraying water over the brushes, and the water passes a filter shelf being recirculated back to the water tank below the washer cabinet.

To obtain an efficient cleaning a detergent is added to the wash water, which is warmed up to 48°C by direct steam injecon, or alternavely by an indirect steam heang system.

The side doors give excellent access to the brush and spray modules, which are easily removed for inspecon and cleaning.

FEATURES:

- Removable brush & spray modules

- Slanng brushes for maximum egg-to-brush contact and gentle washing

- Adjustable brush system for different egg sizes

- Different brush types (so or hard)

- High volume low-pressure water supply system maximizes cleaning and reduces damage of the eggs

OPTIONS:

- CIP cleaning (only certain models)

- High-Intensity Egg Candling System

- Rotary Filtering System for cleaning of wash water and lower BOD in wastewater

- Pre-rinse systems (soaking)

- Final rinse and sanizing systems

SAFETY AND SERVICE

All AQUA ART & ENGINEERING products and systems are designed to meet the industry safety standards.

A comprehensive service organizaon is always available to assist in the selecon of the right maintenance programmed or individual spare part.

Egg washer model

Recommended Capacity(cases/h): 60 cph

(Egg/H): 1200 eggs/h

Matching egg Breaker: SB/SBS 1000 Opti Breaker Compact 2

Number of rows: 6

Available washer length (meter): 1.2

Wash system: Double-action (Brushes)

Type of brushes: Egg-shape

Drying method: Direct Blower air

Tubular Heat Exchanger: No

Electrical Heating: No

Candling: No

Rotary filter: Yes

CIP: Yes

Pre rinse system: Yes

Sanitizer: No

Labelling Machine: Yes

Oiling Process: No

Recommended Capacity(cases/h): 185 cph

(Egg/H): 6000 eggs/h

Matching egg Breaker:

Opti Breaker Basic 5

Opti Breaker Basic 6

Opti Breaker Compact 6

Opti Breaker 6

Number of rows: 6

Available washer length (meter): 2.2, 4.4, 6.8, 8.8

Wash system: Double-action (Brushes and Spray modules)

Type of brushes: Slanted

Drying method: Direct Blower air

Tubular Heat Exchanger: No

Electrical Heating: Yes

Candling: No

Rotary filter: No

CIP: No

Pre rinse system: No

Sanitizer: No

Labelling Machine: No

Oiling Process: No

Recommended Capacity(cases/h): 250 cph

(Egg/H): 9000 eggs/h

Matching egg Breaker:

Opti Breaker Compact 8

Opti Breaker 8

Number of rows: 8

Available washer length (meter): 2.2, 4.4, 6.8, 8.8

Wash system: Double-action (Brushes and Spray modules)

Type of brushes: Slanted

Drying method: Direct Blower air

Tubular Heat Exchanger: No

Electrical Heating: Yes

Candling: No

Rotary filter: No

CIP: No

Pre rinse system: No

Sanitizer: No

Labelling Machine: No

Oiling Process: No

Recommended Capacity(cases/h): 375 cph

(Egg/H): 12000 eggs/h

Matching egg Breaker:

Opti Breaker Compact 12

Opti Breaker 12

Number of rows: 12

Available washer length (meter): 2.2, 4.4, 6.8, 8.8

Wash system: Double-action (Brushes and Spray modules)

Type of brushes: Slanted

Drying method: Direct Blower air

Tubular Heat Exchanger: No

Electrical Heating: Yes

Candling: No

Rotary filter: No

CIP: No

Pre rinse system: No

Sanitizer: No

Labelling Machine: No

Oiling Process: No

Recommended Capacity(cases/h): 500 cph

(Egg/H): 18000 eggs/h

Matching egg Breaker:

Opti Breaker 16

Number of rows: 16

Available washer length (meter): 2.2, 4.4, 6.8, 8.8

Wash system: Double-action (Brushes and Spray modules)

Type of brushes: Slanted

Drying method: Direct Blower air

Tubular Heat Exchanger: No

Electrical Heating: Yes

Candling: No

Rotary filter: No

CIP: No

Pre rinse system: No

Sanitizer: No

Labelling Machine: No

Oiling Process: No