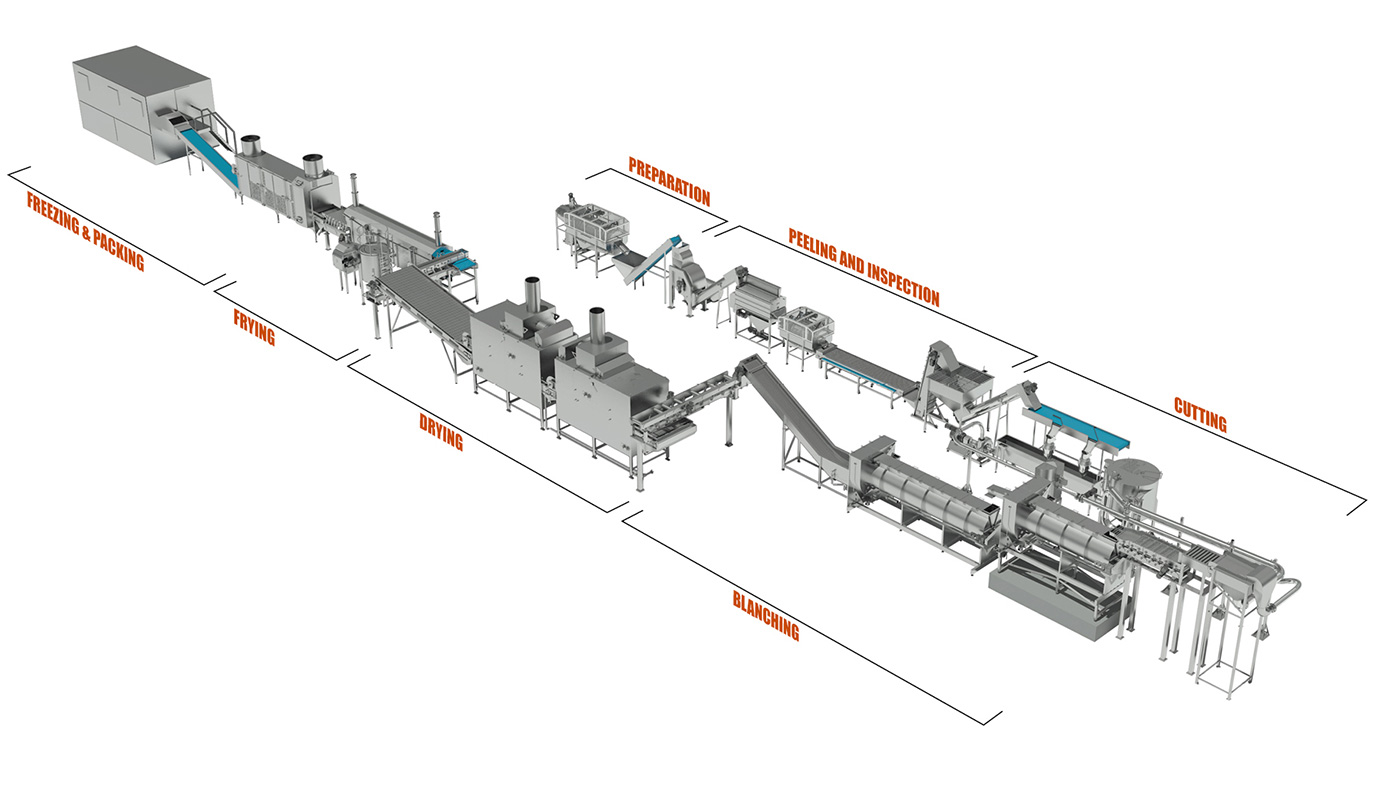

French Friess Production Line

The Process

STEP 1: PREPARATION

As potatoes are received, they are sorted and pre-graded to correspond with the type of French fry to be produced. Potatoes then enter the line and pass through the destoner and washing process, before being peeled.

STEP 2: STEAM PEELING AND INSPECTION

After steam peeling, the de skinner removes and collects the peel waste, and the potatoes are then washed clean prior to being inspected and transported to the cutting process.

STEP 3: CUTTING

The cutting process is performed by either a hydro-cutting or mechanical cutting system. These machines cut the potato into stripscrinkle d or straight, to the desired size, and then pass the strips through equipment that removes slivers and nubbins.

STEP 4: BLANCHING

The potato strip then passes through a blanching system, consisting of two or more screw blanchers. Here the strips are gelatinized and the sugar levels reduced, then they go through the SAPP—dipping belt, before being pre-dried.

STEP 5: DRYING

During the drying process (which is optional for smaller lines), the moisture content is reduced, and the strips are now ready for the frying process, where the final texture and color are achieved. Before entering the fryer the French fries are transported on the Equilibration belt to get an even moisture content.

STEP 6: MULTIZONE FRYING

With controlled oil flows together with the Multizonedesign and the belt return outside the fryer, Rosenqvist’s frying system will give you the best tools to achieve the desired texture and color. After frying, the French fries will pass a defatting step. For coated fries and other potato products, a batter and pre-frying the step is added before the normal frying system.

STEP 7: FREEZING & PACKING

After the defatting step, the golden French fries will enter the freezer, on their way to the packaging system. The line can also be equipped with a pre-cooler installed before the freeze.

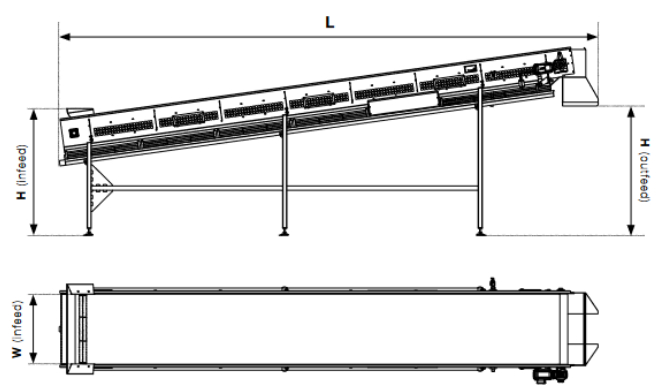

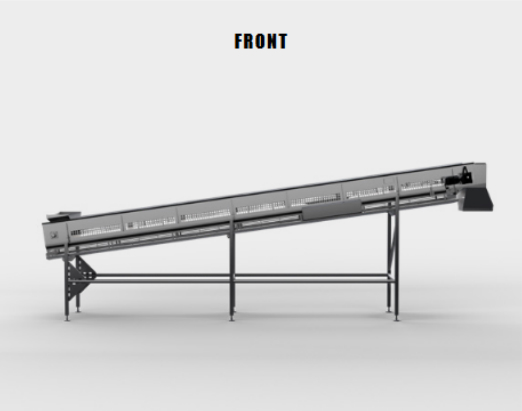

INSPECTION BELT

In various parts of processing lines, there is a need to inspect the product for quality reasons or for final product reasons. The Inspection Belt can be modified and adopted to each line and product requirement. The stainless-steel framework has an eyelink belt as standard. The speed of the belt is adjustable. As optional the inspection belt can be supplied with other belt types or working platform etc.

INSPECTION BELT ADVANTAGES

Adjustable belt speed

Stainless-steel eyelink belt as standard

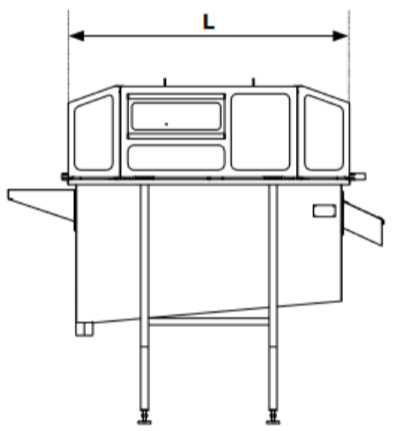

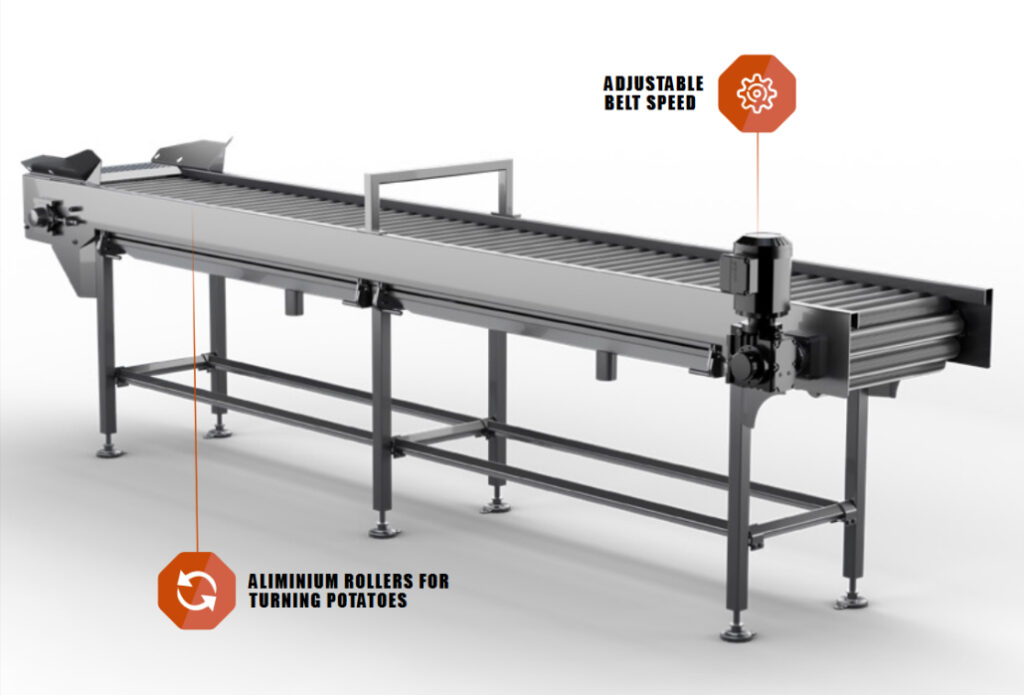

ROLLER INSPECTION TABLE

The need for manual inspection of all types of food products varies depending on the season and quality of the incoming products. The Roller Inspection Table has specially designed aluminum rollers. This ensures that the products turn and expose the entire surface to the staff at the inspection table. The speed of the rollers can be easily adjusted. The cut trimmings are collected in a container. The Roller Inspection Table can also be supplied with individual cutting plates for each inspector(optional).

Inspection Table Advantages

Adjustable belt speed

Aliminium rollers for turning potatoes

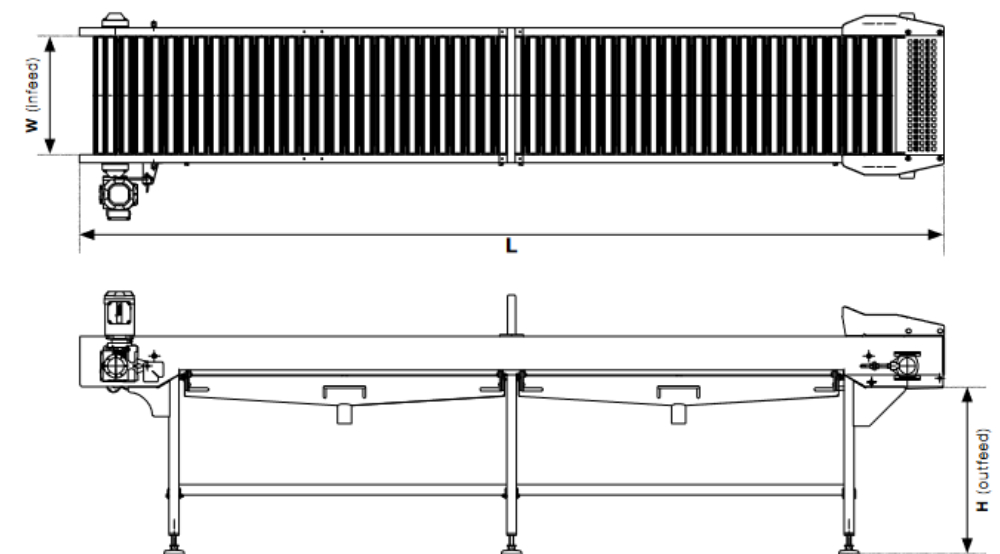

Roller Inspection Table

L(mm): 3000

W INFEED(mm): 600, 800, 1000

H OUTFEED(mm): 700

INSTALLED POWER: 0.75 kw

L(mm): 4000

W INFEED(mm): 600, 800, 1000

H OUTFEED(mm): 700

INSTALLED POWER: 0.75 kw

L(mm): 5000

W INFEED(mm): 600, 800, 1000

H OUTFEED(mm): 700

INSTALLED POWER: 0.75 kw

L(mm): 6000

W INFEED(mm): 600, 800, 1000

H OUTFEED(mm): 700

INSTALLED POWER: 0.75 kw

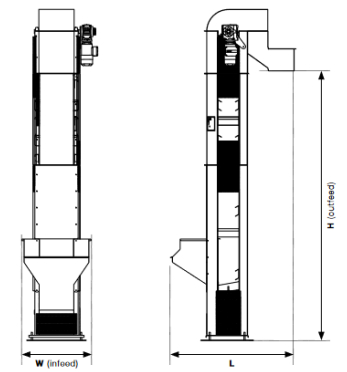

VERTICAL ELEVATOR

The Vertical Elevator provides a very spaceefficient solution for elevating products. The products are collected in a buffer hopper and the specially designed plastic belts with integrated lifters elevate the products to the desired height. A chute arrangement designed for the next machine will ensure that products are evenly fed forward. The Vertical Elevator belt speed can be adjusted to control the feeding rate to the next processing stage. Larger buffer hoppers can be supplied (optional).

VERTICAL ELEVATOR ADVANTAGES

Adjustable belt speed

Potato buffer to create an even feeding

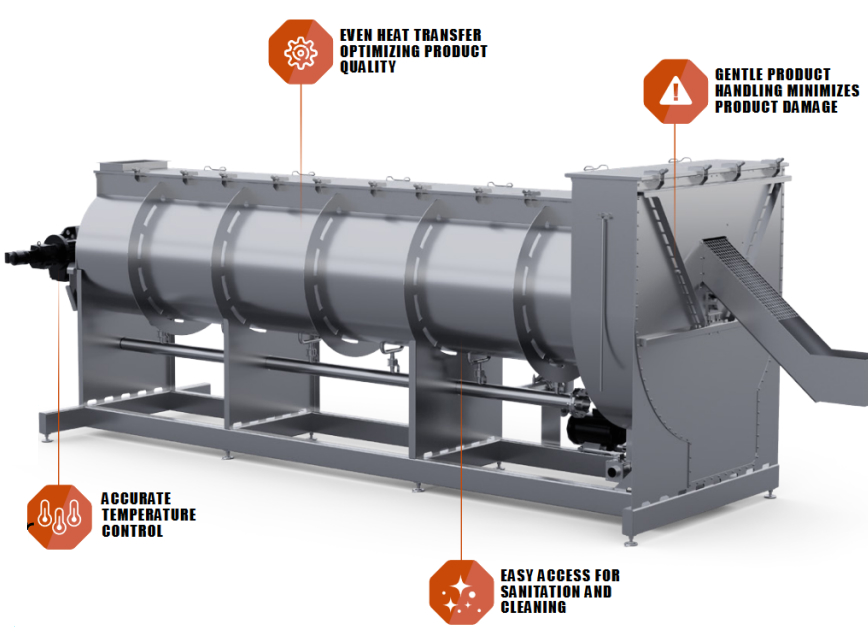

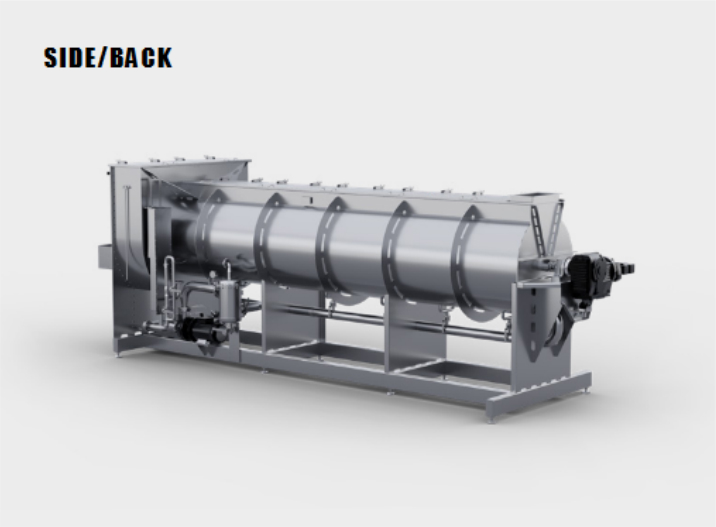

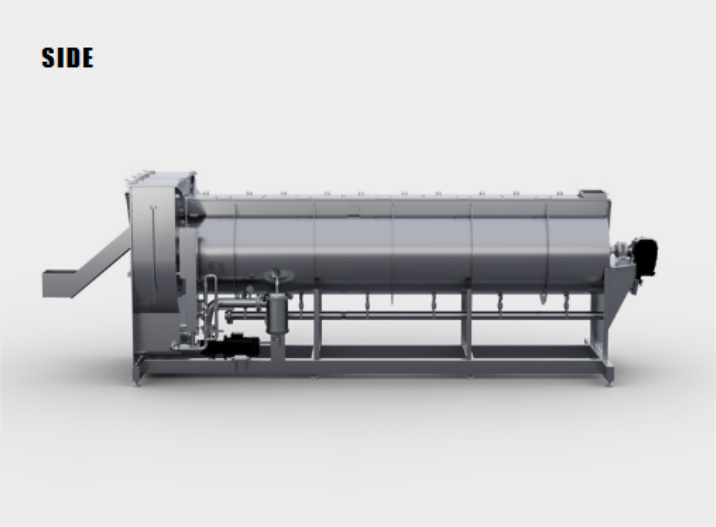

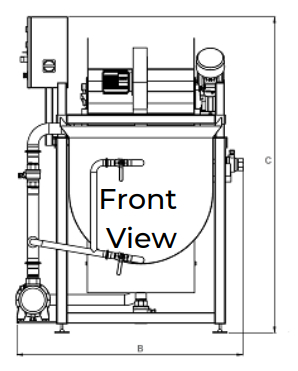

AUGER BLANCHER

The cut or whole products need to be blanched (gelatinize the starch cells) and sugar needs to be leaked out before the next processing step that can be either drying, cooking or frying, depending what final product being processed. The blancher handles the product gently to minimize breakages. In a French Fry line, normally a two step blanching process is used to get the best combination of heat treatment and sugar leakage. In the auger blancher, the water is heated to the desired temperature. Heating is made through direct injection of steam (4–6 bar) in the water circulation pipe and the temperature is maintained at +/- 1 degree C. The auger is conveying the product along the screw blancher. Retention times to be adjustable between 3–60 minutes. The auger is perforated and the design allows for a close tolerance between the auger and the blancher body.

At the out feed end of the auger, a ferris wheel lifts the product to the discharge chute. As option, the auger blancher can be supplied with a belt out feed arrangement. On top of the auger blancher, hatches are placed along the unit for easy access and cleaning.

AUGER BLANCHER ADVANTAGES

Accurate temperature control

Even heat transfer optimizing product quality

Gentle product handling minimizes product damage

easy access for sanitation and cleaning

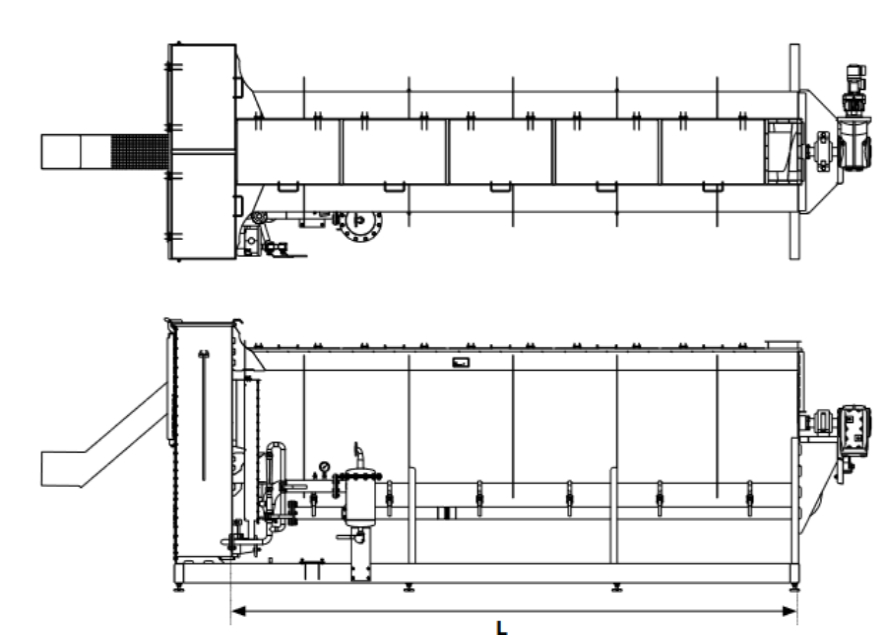

Auger Blancher

Auger Diameter (mm): 700

Auger Length L (mm): 2000

Volume (L) : 500

Capacity Kg Product Per Hour At Blanching Time Of:-

10 Min: 350

25 Min: 850

Auger Diameter (mm): 700

Auger Length L (mm): 3000

Volume (L) : 800

Capacity Kg Product Per Hour At Blanching Time Of:-

10 Min: 500

25 Min: 1250

Auger Diameter (mm): 900

Auger Length L (mm): 2500

Volume (L) : 1200

Capacity Kg Product Per Hour At Blanching Time Of:-

10 Min: 700

25 Min: 1750

Auger Diameter (mm): 900

Auger Length L (mm): 4500

Volume (L) : 2000

Capacity Kg Product Per Hour At Blanching Time Of:-

10 Min: 1250

25 Min: 3150

Auger Diameter (mm): 1200

Auger Length L (mm): 4000

Volume (L) : 3000

Capacity Kg Product Per Hour At Blanching Time Of:-

10 Min: 1950

25 Min: 4800

Auger Diameter (mm): 1200

Auger Length L (mm): 6000

Volume (L) : 4500

Capacity Kg Product Per Hour At Blanching Time Of:-

10 Min: 2900

25 Min: 7200

Auger Diameter (mm): 1500

Auger Length L (mm): 5000

Volume (L) : 6000

Capacity Kg Product Per Hour At Blanching Time Of:-

10 Min: 3800

25 Min: 9400

Auger Diameter (mm): 1800

Auger Length L (mm): 5000

Volume (L) : 9000

Capacity Kg Product Per Hour At Blanching Time Of:-

10 Min: 5450

25 Min: 13500

Auger Diameter (mm): 1800

Auger Length L (mm): 6500

Volume (L) : 12000

Capacity Kg Product Per Hour At Blanching Time Of:-

10 Min: 7050

25 Min: 17600

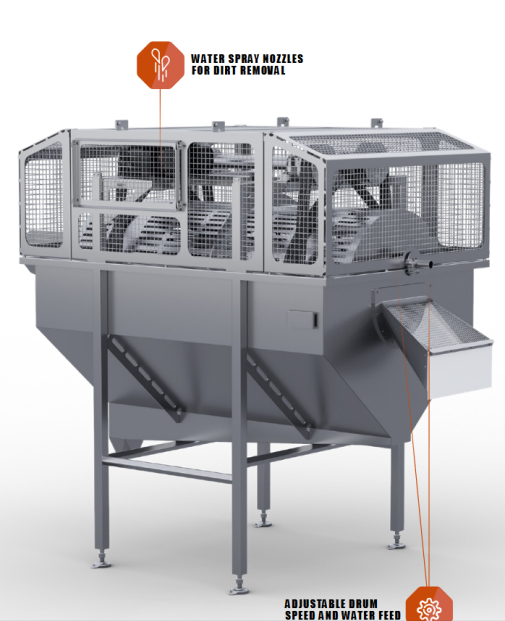

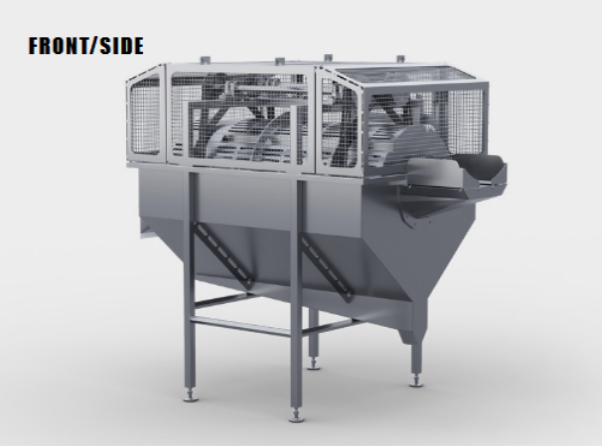

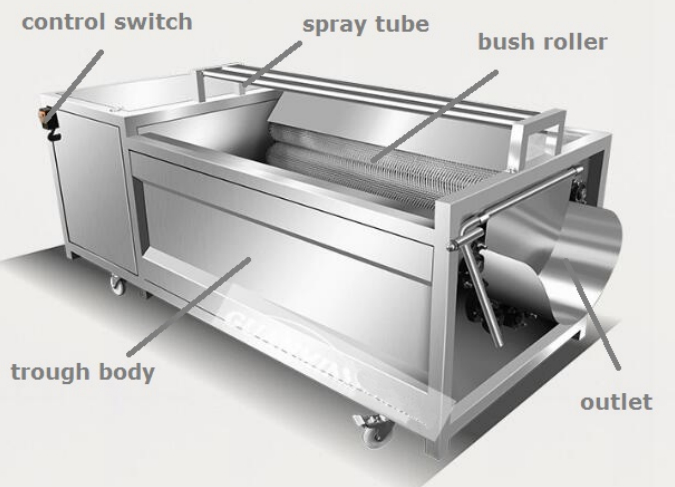

DRUM TYPE WASHER

Drum washer best option for the root type food products which contain more dust then other than other produce. It is desired that all type of root vegetables are washed before inspection and further processing. The rotating drum washes the vegetables gently. Along the drum length, water spray nozzles are placed. The drum is mounted in a belt drive arrangement. The amount of feeding water and the speed of the drum are adjuastable.

After Washer Advantages

Water spray nozzles for dirt removal

Adjustable drum speed and water feed

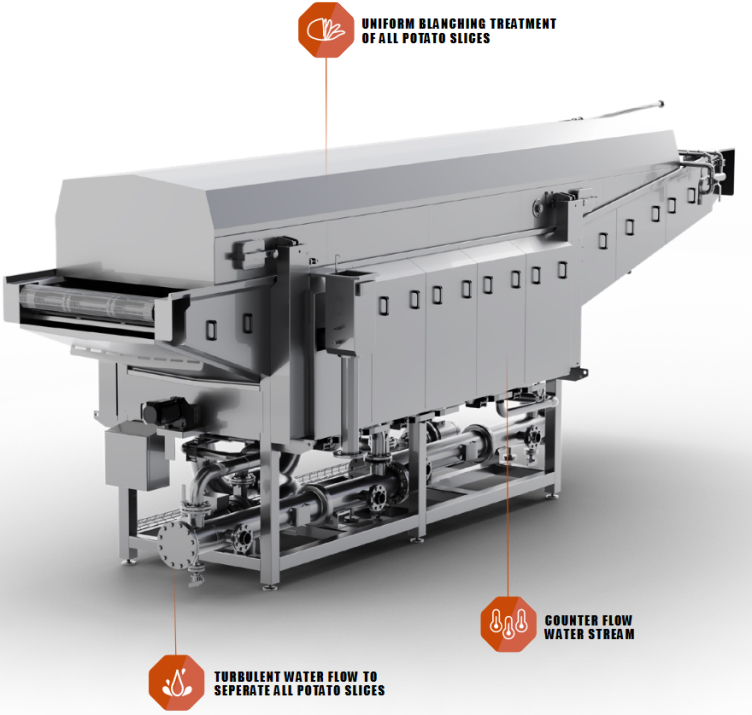

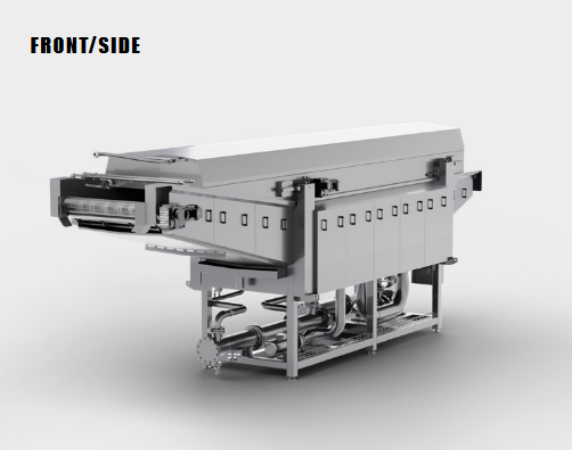

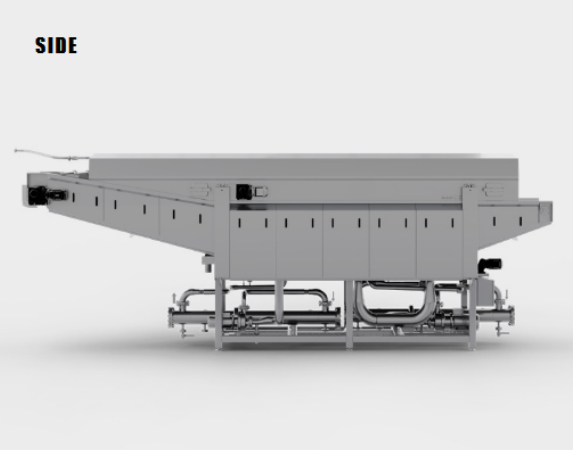

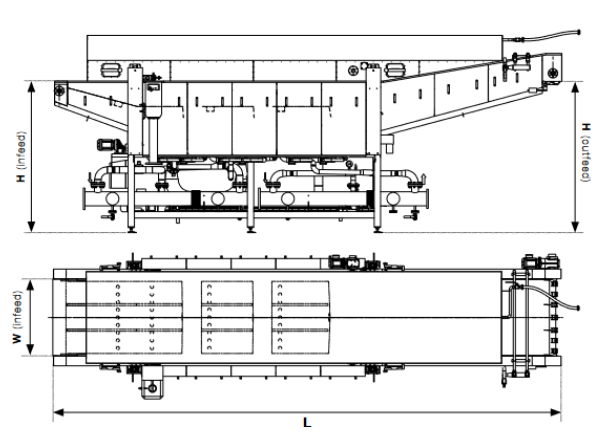

CONTINOUS TYPE BLANCHER

In the potato chip process, starch is converted to sugar. The frying process reveals the amount of sugar by darkening the color. The darker the color of the potato chips, the higher the sugar content. In order to reduce the sugar content of the potato chips, the sugar has to be removed from the slices. This process is called blanching. Rosenqvists counter flow Multi Turbulent Blancher uses hot water. Each slice is separated and treated individually.

The Multi Turbulent Blancher has four main parts:

• Hood with a paddle belt

• Pan with multiple water intake and outlets in the bottom, were water is injected along both sides

• Bottom belt can be used for transportation when there is no need for blanching

As the slices enter the first zone of the blancher, the paddle belt ensures that a constant number of slices are conveyed through the machine. All slices are treated uniformly and for the same amount of time. The injectors create a turbulent water flow which separates the slices resulting in even heat treatment. The water can be heated by either thermo oil or direct injected steam.

Fresh water is added via a spray ramp above the discharge section. The water discharge is placed at the infeed. Due to the counter flow main water stream, the water in the process is used with optimal efficiency. The Multi Turbulent Blancher adjusts the temperature of the water for desired product profile.

MULTI TURBULENT BLANHER ADVANTAGES

Uniform blanching treatment of all potato silces

Turbulent water flow to seperate all potato slices

Counter flow water stream

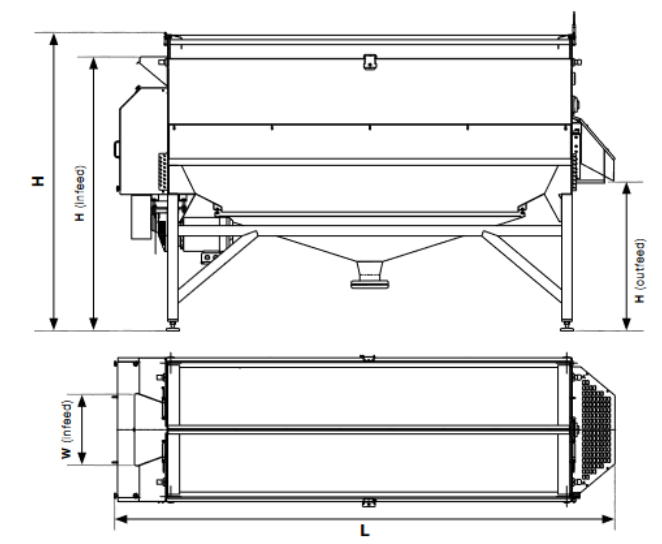

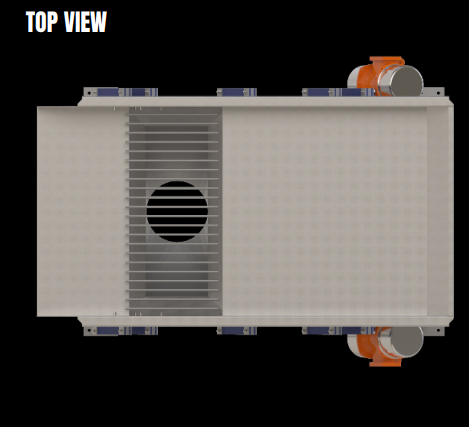

Multi turbulent Blancher

L(belt area m2): 6940

W (mm): 700

H INFEED: Min. 2070

H OUTFEED: Min. 2050

SLICE CAPACITY: 1300kg/h

INSTALLED POWER: 18 KW

L(belt area m2): 6940

W (mm): 900

H INFEED: Min. 2070

H OUTFEED: Min. 2050

SLICE CAPACITY: 1700kg/h

INSTALLED POWER: 18 KW

L(belt area m2): 7440

W (mm): 1100

H INFEED: Min. 2070

H OUTFEED: Min. 2050

SLICE CAPACITY: 2600kg/h

INSTALLED POWER: 18 KW

L(belt area m2): 7940

W (mm): 1100

H INFEED: Min. 2070

H OUTFEED: Min. 2050

SLICE CAPACITY: 3100kg/h

INSTALLED POWER: 18 KW

L(belt area m2): 8440

W (mm): 1300

H INFEED: Min. 2070

H OUTFEED: Min. 2050

SLICE CAPACITY: 4300kg/h

INSTALLED POWER: 25 KW

L(belt area m2): 8940

W (mm): 1600

H INFEED: Min. 2070

H OUTFEED: Min. 2050

SLICE CAPACITY: 6000kg/h

INSTALLED POWER: 25 KW

L(belt area m2): 9440

W (mm): 1800

H INFEED: Min. 2070

H OUTFEED: Min. 2050

SLICE CAPACITY: 7600kg/h

INSTALLED POWER: 25 KW

L(belt area m2): 10440

W (mm): 1800

H INFEED: Min. 2070

H OUTFEED: Min. 2050

SLICE CAPACITY: 9300kg/h

INSTALLED POWER: 25 KW

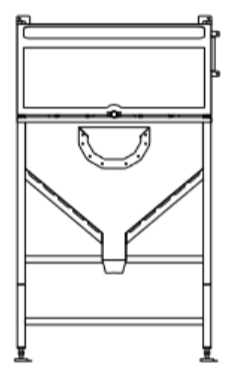

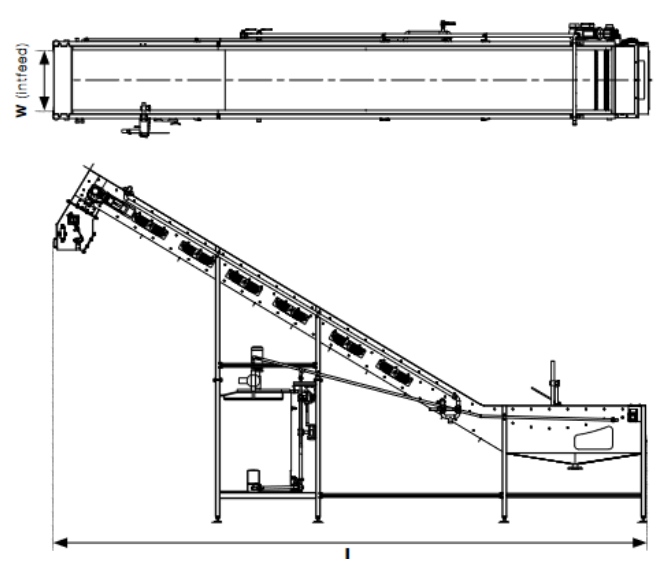

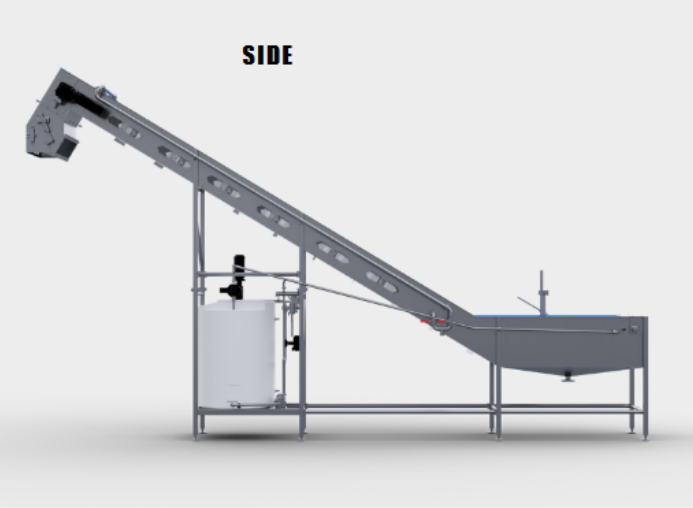

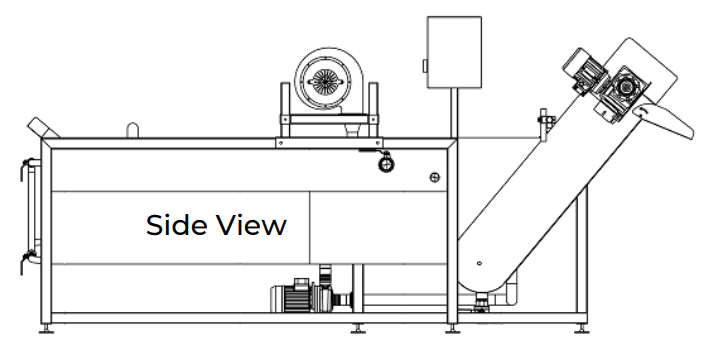

ELEVATOR

In the potato processing line, the processed product may need to be dipped in a solution. The dipping elevator ensures that the product is immersed in the solution and conveyed to the next processing step after the required application time. The dipping elevator has a stainless steel eye link belt. Flights are mounted along the belt. The hopper at the infeed is designed to hold the solution and ensures that each piece of the product is immersed in the solution. The adjustable belt speed controls the holding time-end transfers the product evenly to the next processing step. As optional a blending and dosing tank can be offered. The size and type are to be decided upon request.

DIPPING ELEVATOR ADVANTAGES

Adjustable belt speed

Stainless steel eyelink belt with flights

Dipping tub for complete coverage of liqiuid solution

Dosing tank

ABRASIVE PEELER

CONTINUOUS ABRASIVE PEELER

The Continuous Abrasive Peeler is suitable for peeling potatoes, carrots and other root vegetables. Keeping the water usage to a minimum and ensuring the lowest possible material losses during peeling, are very important factors when choosing a peeling system for your process, since the result of peeling for each individual potato will affect the quality of your finished product.

The Continuous Abrasive Peeler has eight high–speed rollers. The rollers can have different gauges of coated abrasive material depending on the desired peeling effect. Specially selected coating material and the coating process combine to make the rollers very durable and long lasting. The abrasive rollers can be replaced by nylon brushes for optimum effect when preparing fresh potatoes or when the unit is used for deskinning.

The rollers of the Continuous Abrasive Peeler rotate at a very high speed and the centrifugal force generated by it removes the peel waste. A minimum of fresh water is used for rinsing. All eight rollers can easily be exchanged if nylon brushes or a new roller set is required.

A central auger conveys the potatoes through the length of the peeler. By adjusting the auger speed and the speed of the abrasive rollers, the desired degree of peeling is achieved. Speeds are adjusted via frequency converters placed in the control panel.

Two covers at the top of the unit can be easily opened for cleaning. The peeler has central lubrication points for the infeed and discharge bearing components. The Continuous Abrasive Peeler can also be supplied with a peel waste pump system (optional). With such a system in place, the waste is pumped to an external container or waste area.

CONTINUOUS ABRASIVE PEELER ADVANTAGES

Adjustable auger speed for accurate peeling

Eight high speed rollers for peeling

Continuous Abrasive Peeler

L (mm) :3100

W (mm) : 1000(400/340)

H (mm) : 2360(2160/1180)

Installed Power : 0.25 kw

L (mm) : 3800

W (mm) : 1100(460/520)

H (mm) : 2840(2620/1720)

Installed Power : 0.25 kw

VIBRATION DEWATERING TABLE

We build dewatering shakers in all shapes and sizes, it is an excellent technical solution for subsequently separating the water from the product. A shaker is a very hygienic and effective solution since the vibratory conveyor technology enables the shaker to break the water surface or drops of liquid on the products and remove the water.

The decks can be manufactured customspecific with wire mesh, wedge wire, perforated metal sheets or bars. The decks are easily replaceable – they are equipped with a quick tension system – so that the dewatering shaker can be used to transport and dewater multiple sorts and types of products.

Batch Type Vegetable Washer Advantages

Easy to use

Require Less Men Power

VIBRATION TABLE

BATCH TYPE OF ROLLER PEELER

The Batch type roller Peeler is suitable for peeling potatoes, carrots, Ginger, Potatoes, and other root vegetables.Keeping the water usage to a minimum and ensuring the lowest possible material losses during peeling is a very important factors when choosing a peeling system for your process, since the result of peeling for each individual potato will affect the quality of your finished product.

The Batch type of roller Peeler has eight high–speed rollers. Specially selected coating material and the coating process combine to make the rollers very durable and long-lasting. The Nylon rollers can be replaced by Abrasive rollers for optimum effect when preparing fresh potatoes or when the unit is used for deskinning. All eight rollers can easily be exchanged if nylon brushes or a new roller set is required. A central auger conveys the potatoes through the length of the peeler. By adjusting the auger speed and the speed of the abrasive rollers, the desired degree of peeling is achieved. Speeds are adjusted via frequency converters placed in the control panel.

BATCH TYPE OF ROLLER PEELER

Easy to use

Require less space and power.

CONTINUOUS TYPE VEGETABLE WASHER

Industrial Fruit and Vegetable Washing Machine, also known as commercial fruit and vegetable washing machine, it is specially designed for cleaning fruits and vegetables, herbs. Our fruit and vegetable washer adopts high-pressure spray, bubble surfing, drum filtering and ultrasonic vibration or Ozone cleaning methods to thoroughly clean the dirt on the surface of vegetables and fruits. Besides, during the cleaning process, an appropriate amount of fungicide can also be added to clean vegetables and remove pesticide residues. While cleaning, materials can be washed completely and thoroughly without damages to material surfaces, taste, and nutrition of materials. The purified water filtered by activated carbon can be recycled, saving 80% of water. Our fruit and vegetable washer was widely used at the food processing plants and business.

Batch Type Vegetable Washer Advantages

Turbulant water flow/bubbles to wash all product separatly.

Adjustable conveyor speed and water flow.

WASHER

VEGETABLEAIR DRYING MACHINE

Air Knife Dewatering Machine is used for dewatering and drying hard and soft vegetable, salad, bay leaf, cut lettuce as well as fruit, etc. Air Knife Dewatering Machine can be optimized for removing excess surface moisture from products such as vegetables, salad, and fruit while keeping the product in perfect condition. With the possible adjustment, the machine can be optimized on product quality, residual moisture, and capacity. The product is transported on a conveyor belt and the speed of the belt is adjustable depending on the product. Several special air knives and blowers are dewatering the product whereas several blowers are distributing it over the whole width of the conveyor above each air knife. An air knife at the outfeed removes any remaining product from the conveyor belt.