CONTINOUS TYPE BLANCHER

In the potato chip process, starch is converted to sugar. The frying process reveals the amount of sugar by darkening the color. The darker the color of the potato chips, the higher the sugar content. In order to reduce the sugar content of the potato chips, the sugar has to be removed from the slices. This process is called blanching. Rosenqvists counter flow Multi Turbulent Blancher uses hot water. Each slice is separated and treated individually. Junto con nuestros productos, también recomendamos visitar spin casino bonos sin deposito y jugar allí.

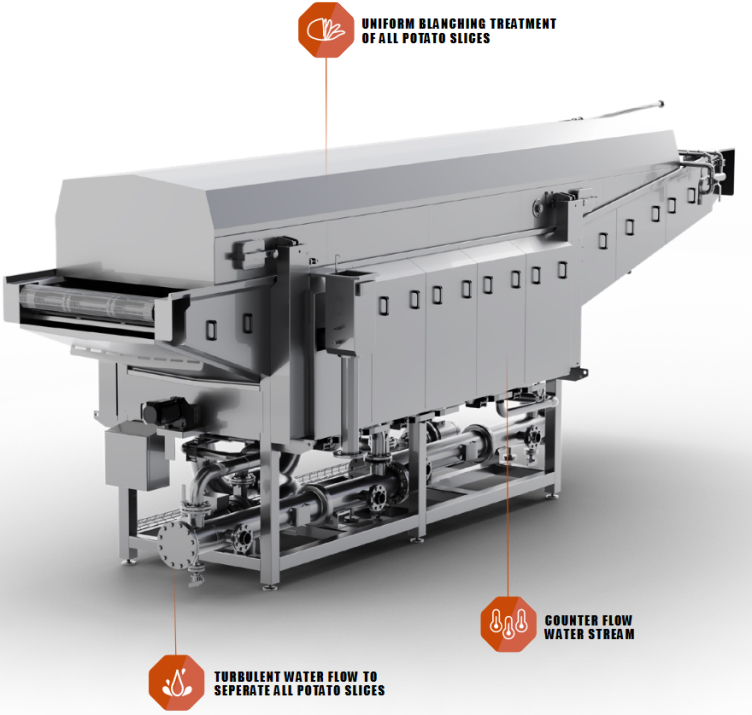

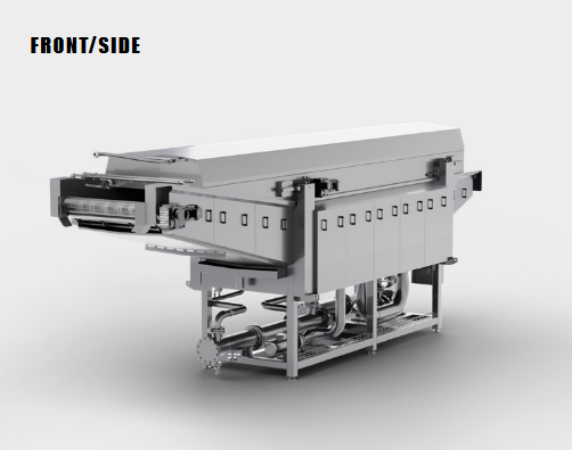

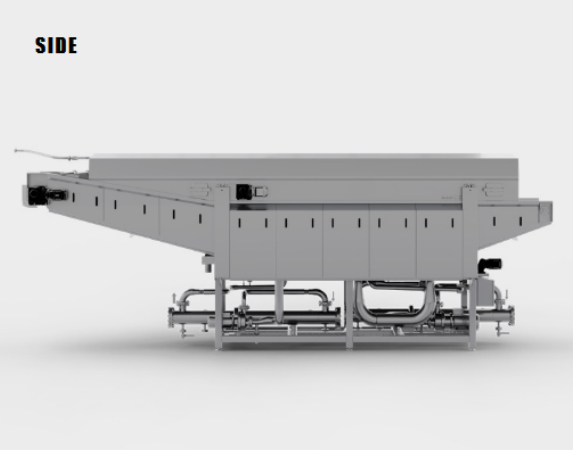

The Multi Turbulent Blancher has four main parts:

• Hood with a paddle belt

• Pan with multiple water intake and outlets in the bottom, were water is injected along both sides

• Bottom belt can be used for transportation when there is no need for blanching

As the slices enter the first zone of the blancher, the paddle belt ensures that a constant number of slices are conveyed through the machine. All slices are treated uniformly and for the same amount of time. The injectors create a turbulent water flow which separates the slices resulting in even heat treatment. The water can be heated by either thermo oil or direct injected steam.

Fresh water is added via a spray ramp above the discharge section. The water discharge is placed at the infeed. Due to the counter flow main water stream, the water in the process is used with optimal efficiency. The Multi Turbulent Blancher adjusts the temperature of the water for desired product profile.

MULTI TURBULENT BLANHER ADVANTAGES

Uniform blanching treatment of all potato silces

Turbulent water flow to seperate all potato slices

Counter flow water stream

Multi turbulent Blancher

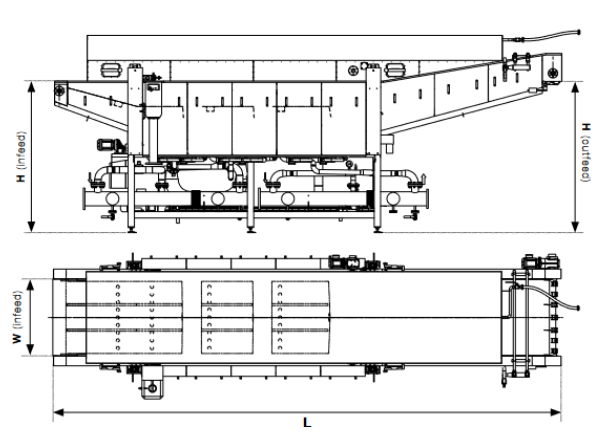

L(belt area m2): 6940

W (mm): 700

H INFEED: Min. 2070

H OUTFEED: Min. 2050

SLICE CAPACITY: 1300kg/h

INSTALLED POWER: 18 KW

L(belt area m2): 6940

W (mm): 900

H INFEED: Min. 2070

H OUTFEED: Min. 2050

SLICE CAPACITY: 1700kg/h

INSTALLED POWER: 18 KW

L(belt area m2): 7440

W (mm): 1100

H INFEED: Min. 2070

H OUTFEED: Min. 2050

SLICE CAPACITY: 2600kg/h

INSTALLED POWER: 18 KW

L(belt area m2): 7940

W (mm): 1100

H INFEED: Min. 2070

H OUTFEED: Min. 2050

SLICE CAPACITY: 3100kg/h

INSTALLED POWER: 18 KW

L(belt area m2): 8440

W (mm): 1300

H INFEED: Min. 2070

H OUTFEED: Min. 2050

SLICE CAPACITY: 4300kg/h

INSTALLED POWER: 25 KW

L(belt area m2): 8940

W (mm): 1600

H INFEED: Min. 2070

H OUTFEED: Min. 2050

SLICE CAPACITY: 6000kg/h

INSTALLED POWER: 25 KW

L(belt area m2): 9440

W (mm): 1800

H INFEED: Min. 2070

H OUTFEED: Min. 2050

SLICE CAPACITY: 7600kg/h

INSTALLED POWER: 25 KW

L(belt area m2): 10440

W (mm): 1800

H INFEED: Min. 2070

H OUTFEED: Min. 2050

SLICE CAPACITY: 9300kg/h

INSTALLED POWER: 25 KW