Service

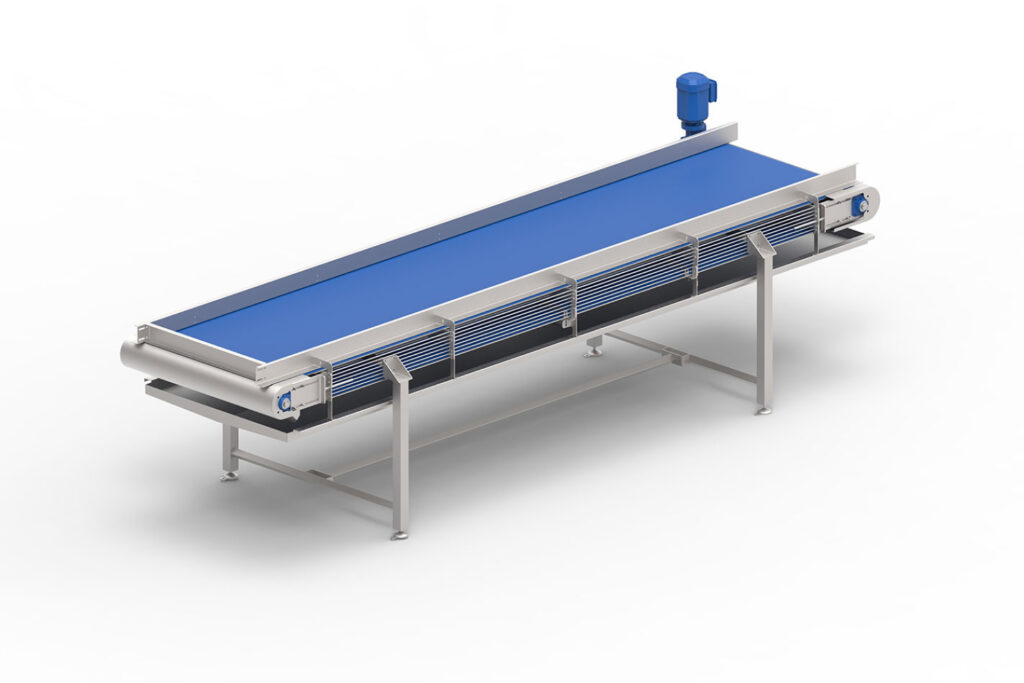

Inspection Conveyor Belt

In various parts of processing lines, there is a need to inspect the product for quality reasons for final product reasons. The Inspection Belt can be modified and adapted to each line and product requirement. The stainless-steel framework has an eyeblink belt as standard. The speed of the belt is adjustable.

As optional the inspection belt can be supplied with other belt types or working platforms etc.

Capacity:- 100KGH TO 10,000KGH

Elevator Conveyor Belt

The Elevator conveyor provides a very space-efficient solution for elevating products. The products are collected in a buffer hopper and the specially designed plastic belts with integrated lifters elevate the products to the desired height. A chute arrangement designed for the next machine will ensure that products are evenly fed forward. The Elevator conveyor belt speed can be adjusted to control the feeding rate to the next processing stage. Larger buffer hoppers can be supplied (optional).

Capacity:- 50KGH TO 10,000KGH

Roller Inspection Blet

The need for manual inspection of all types of food products vary depending on the season and quality of the incoming products. The Roller Inspection Table has specially designed aluminum rollers. This ensures that the products turn and expose the entire surface to the staff at the inspection table. The speed of the rollers can be easily adjusted. The cut trimmings are collected in a container. The Roller Inspection Table can also be supplied with individual cutting plates for each inspector (optional).

Capacity :- 50KGH TO 10,000KGH

Egg Washing Line

Egg washers are available in 6-8 rows and 12-16 rows cabinets. With a combination of short and long modules, any washing is achievable. The egg washers can be installed with any egg drying, egg labeling, egg disinfection, egg oiling, egg breaker, and egg grader in the industry. Egg Washers are available with capacities from 500 up to 25000 eggs per hour. The modular washers are available in different lengths and wash mess with a variable number of brush and spray modules for maximum washing performance for different qualities of eggs. The modular system prevents excessive washing with a consequent loss of eggs and reduced yield.

Capacity :- 500Egg/hr To 22,000Egg/hr

Drum Washer

Drum washer best option for root-type food products which contain more dust than other produce. It is desired that all types of root vegetables be washed before inspection and further processing. The rotating drum washes the vegetables gently. Along the drum length, water spray nozzles are placed. The drum is mounted in a belt drive arrangement. The amount of feeding water and the speed of the drum are adjustable.

Capacity :- 250KGH TO 10,000KGH

Continous Type Air Drying

Air Knife or high speed fans Dewatering Machine is used for dewatering and drying hard and soft vegetable, salad, bay leaf, cut lettuce as well as fruit, etc. Air Knife Dewatering Machine can be optimized for removing excess surface moisture from products such as vegetables, salad, and fruit while keeping the product in perfect condition. With the possible adjustment, the machine can be optimized on product quality, residual moisture, and capacity. The product is transported on a conveyor belt and the speed of the belt is adjustable depending on the product. Several special air knives and blowers are dewatering the product whereas several blowers are distributing it over the whole width of the conveyor above each air knife.

Capacity:- 500KGH TO 6000KGH

Batch Type Peeler

The Batch type roller Peeler is suitable for peeling potatoes, carrots, Ginger, Potatoes, and other root vegetables. The Batch type of roller Peeler has eight high–speed rollers. The Nylon rollers can be used for optimum effect when preparing fresh potatoes and other root vegetables or when the unit is used for deskinning. All eight rollers can easily be exchanged if nylon brushes or a new roller set is required.

Capacity:- 100KGH TO 400KGH

Continous Type Emery Peeler

The Continuous type roller is used for continuously peeling the root vegetables. It has an auger with helps the product to travel stationary and peeling uniformly. By adjusting the auger speed and the speed of the abrasive rollers, the desired degree of peeling is achieved. Speeds are adjusted via frequency converters placed in the control panel.

And unloading is continuous.

Capacity:- 500KGH TO 1400KGH

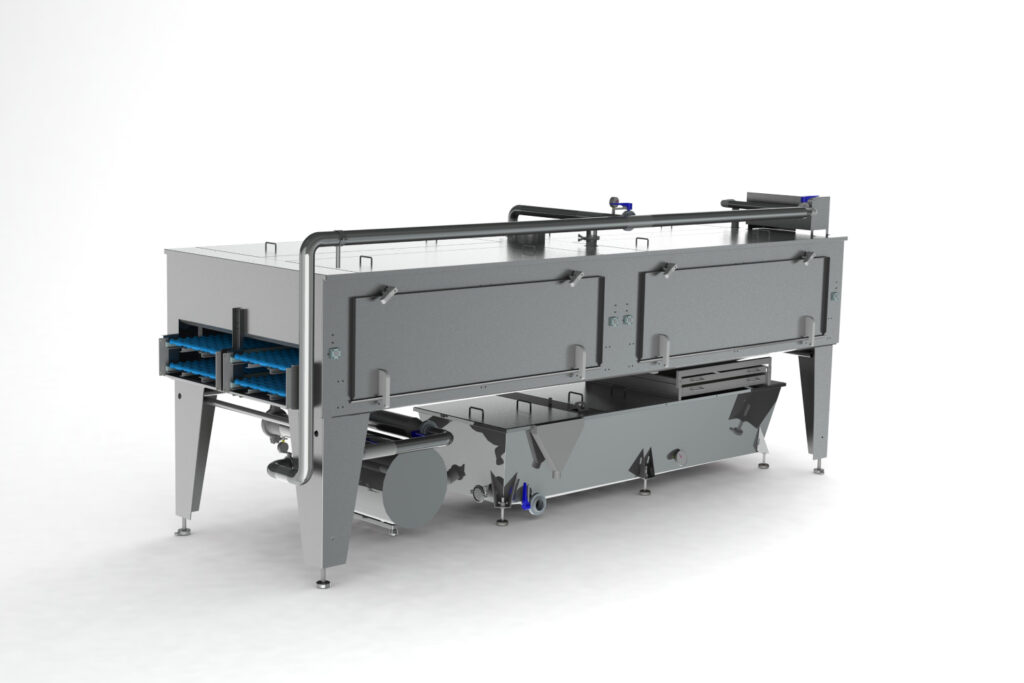

Conveyor Blancher

Blanching application is used in all food processing lines. Like when we set up a frozen vegetable processing plant we require a blancher machine for killing all enzymes and dangerous from the vegetable to maintain its taste. On another side when we use it as a potatoes processing line we use it to reduce the sugar content from potato pieces. The frying process reveals the amount of sugar by darkening the color of sugar is not removed. As the slices enter the first zone of the blancher, the paddle belt ensures that a constant number of slices are conveyed through the machine. All slices are treated uniformly at 70- 90 degrees Celsius and for the same amount of time. The injectors create a turbulent water flow that separates the slices resulting in even heat treatment. The water can be heated by either Electric Heater, thermo oil, or directly injected steam.

Capacity:- 100KGH TO 2,000KGH

Auger Blancher

The Auger blancher is used for the same purposes the only difference is its processing mechanism. The conveyor belt is replaced by an auger rotator. It helps to increase the timing of product traveling. It has an auger with help the product to travel stationary and blanch uniformly. By adjusting the auger speed the desired degree of operation is achieved. Speeds are adjusted via frequency converters placed in the control panel.

Capacity:- 500KGH TO 2,000KGH

Batch Type Vegetable Washer

This machine can be used for cleaning Whole and/or Cutting vegetables, Fruits in Hotels, Flight Caterings, central kitchens, Institutional Kitchens, some new commercial food projects, etc. It has an efficient mechanism for removing mud, soil, and other dirt particles from the various types of food objects. The Machine is designed with a special arc drum (full SS) and washing is complete with help of bubble wash and water spray. An ozone kit is installed inside and help to eliminate all bacteria, virus, etc during the washing operation. It has a linear actuator that helps to lift the basket and unload all produce in the carate. It has SS Ball Valve for controlling the water level.

Capacity:- 50KGH TO 250KGH

Dewatering Vibrator Shaker

We build dewatering shakers in all shapes and sizes, it is an excellent technical solution for subsequently separating the water from the product. A shaker is a very hygienic and effective solution since the vibratory conveyor technology enables the shaker to break the water surface or drops of liquid on the products and remove the water.

The decks can be manufactured custom- specific with wire mesh, wedge wire, perforated metal sheets or bars. The decks are easily replaceable – they are equipped with a quick tension system – so that the dewatering shaker can be used to transport and dewater multiple sorts and types of products.

Capacity:- 100KGH TO 4000KGH

Continous Type Vegetable Washer

Industrial Fruit and Vegetable Washing Machine, also known as commercial fruit and vegetable washing machine are specially designed for cleaning fruits and vegetables, herbs. Our fruit and vegetable washer adopts high-pressure spray, bubble surfing, drum filtering, and ultrasonic vibration or Ozone cleaning methods to thoroughly clean the dirt on the surface of vegetables and fruits. Besides, during the cleaning process, an appropriate amount of fungicide can also be added to clean vegetables and remove pesticide residues. While cleaning, materials can be washed completely and thoroughly without damages to material surfaces, taste, and nutrition of materials. The purified water filtered by activated carbon can be recycled, saving 80% of water. Our fruit and vegetable washer was widely used at the food processing plants and businesses.

Capacity :- 450KGH TO 6,000KGH

Ozone Generator Machines

Understanding ozone treatment is all about understanding processes – and making all components work as one. That’s why we design, manufacture and test all OZONE systems before delivery to ensure efficient, reliable, and cost-effective operation. We wouldn’t have it any other way. Our innovative water treatment OZONE systems provide efficient operation with seamless integration in a multitude of industries and applications worldwide. Our high-performance OZONE systems are implemented to help secure high-quality process water, improve disinfection processes, treat complex industrial wastewater and improve product shelf-life in the food & hygiene sector, process manufacturing, commercial pools, and many other enterprises.

Capacity:- 02GPH TO 400GPH